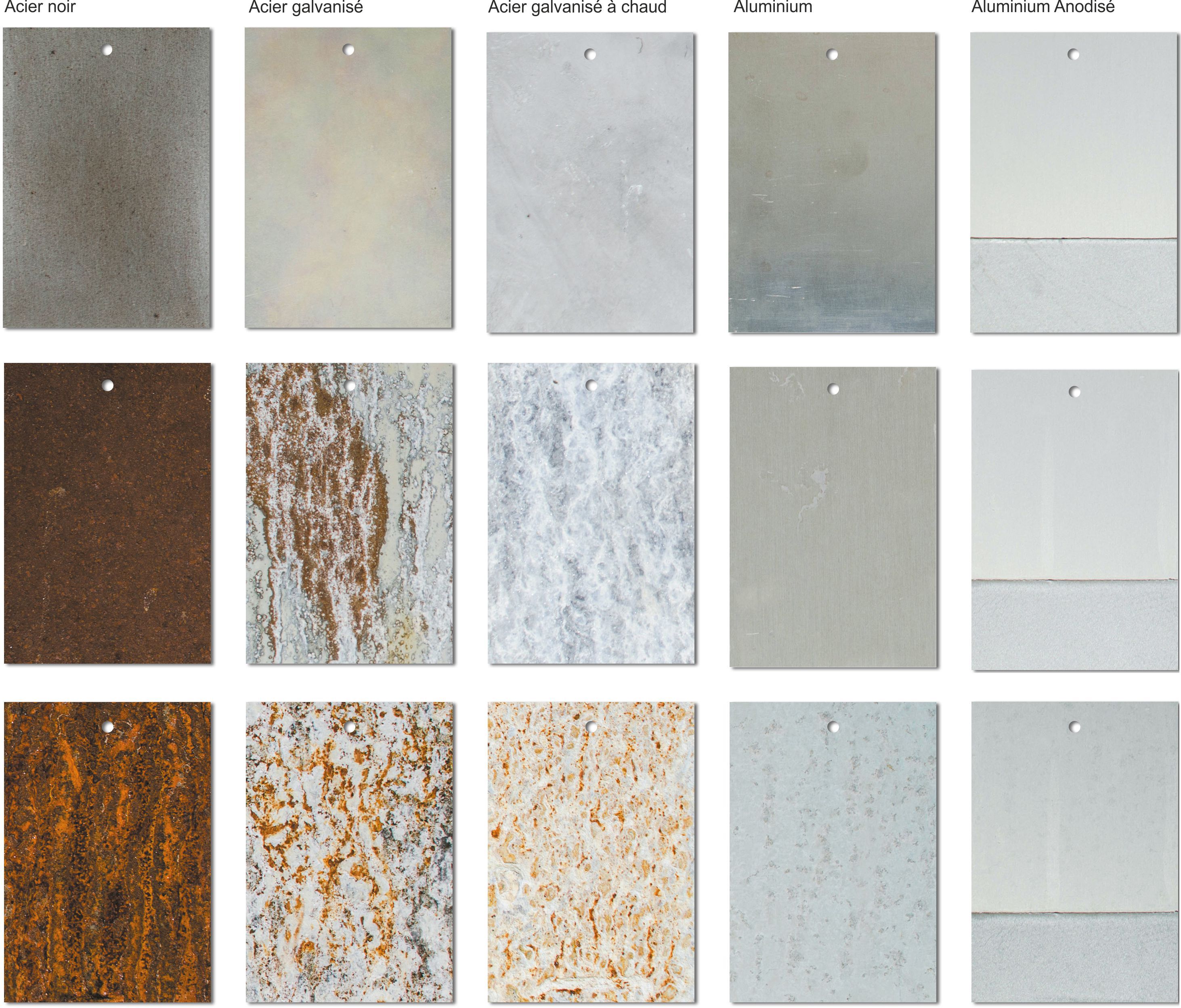

Aluminium

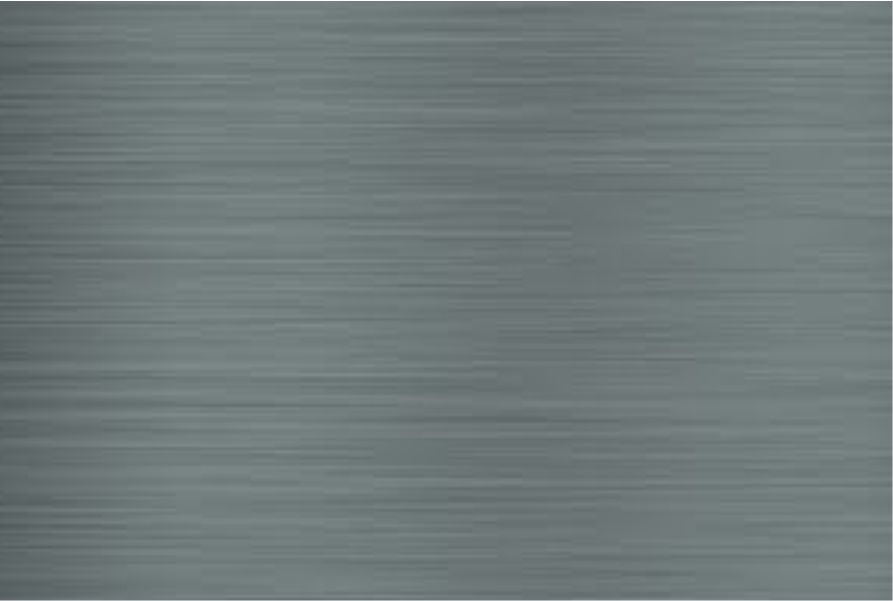

10 Unique Colors of Anodizing

C0 Naturel

C32 Champagne

C33 Olive

C34 Brown

C35 Dark

C45 Stainless Steel

CI63 Grey

CI65 Graphite

CI75 Green

CI78 Anthracite

1.Surface preparation

The first stage of the surface preparation stage is degreasing, consisting of the removal of aluminium surface oils and their derivatives and impurities from the machining parts. Such a cleaned surface is subjected to alkaline digestion, aimed at the removal of a spontaneous oxide film from the surface of the article and to give a uniform matte surface, decorative appearance, and compensates for small defects after rolling or pressing, such as: streaks, thermal and fine stripes.

An alternative finition for satin surfaces is polishing. By means of engraving in a mixture of concentrated acids is carried out smoothing of the surface structure, which reduces the formation of fogging and illuminates the surface of the metal and, consequently, the effect of suitable gloss. Another process of surface preparation of anodizing is more (pickle), the final purpose of which is to remove the thin oxide layer and sludge that may remain after the engraving process or satin-polishing, and removal of what is necessary to obtain a uniform structure oxide coating. luminous

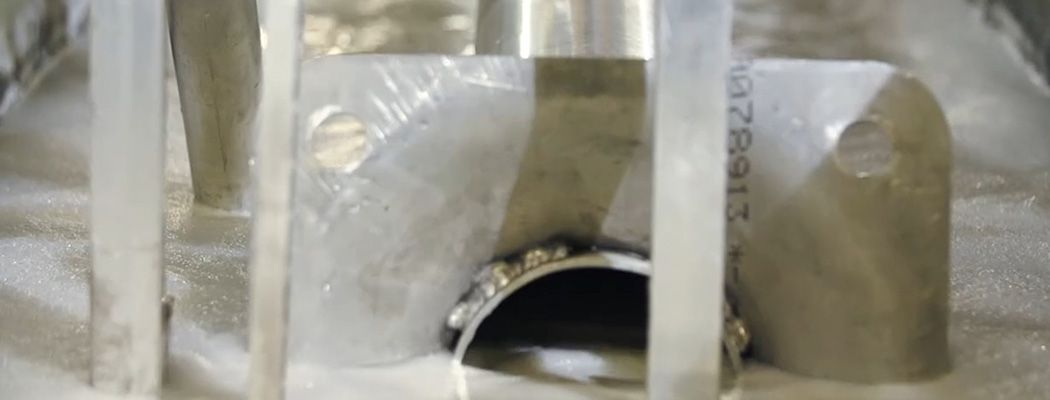

2.anodizing + coloring

Anodizing is the electrochemical preparation of a thin layer of aluminum oxide on the surface of aluminum. The coating is prepared in an aqueous solution of sulfuric acid and the anodized element performs the function of the anode in this process. During electrolysis, after the application of a DC voltage of a certain density to the anode, oxygen is released, which reacts with the metal to form a transparent oxide coating. The coating thus obtained increases by 2/3 of its thickness on the surface of the metal and increases by 1/3 above. It is much thicker than natural, thanks to which it effectively protects aluminum from additional oxidation, namely corrosion. Its porous structure also allows permanent staining of the product by electrochemistry or interference with high resistance to UV radiation.

The electrochemical coloring is based on the treatment of an afterproduct in an electrolyte containing tin ions. The metal, reduced in the cathode cycle, settles at the bottom of the oxide coating pore and gives a permanent color to the aluminum surface. This results in a range of colors from light shades to dark shades from brown to black.

Interference colouration Precedes the anode coating pore shape modification operation. At this stage, the structure of the lower part of the porous layer changes giving it a spherical shape. The modified coating undergoes an electrochemical dyeing process in tin salt baths, thus expanding the color palette obtained in traditional electrochemical staining with shades of gray and green. This method uses the phenomenon of interference - reflected light waves that overlap, leading to an increase or decrease in the amplitude of the resulting wave. The modification of this amplitude by means of an appropriate controlled change in the shape of the pores of the anodic layer makes it possible to obtain the appropriate optical effect (color).

3.Sealig

The final step in anodized sealing technology is the closure of the porous oxide structure. Medium-temperature sealing (86-88°C) involves immersing the product in hot demineralized water with accelerator additives, the purpose of which is to fill the pores of the oxide surface with boehmite. Due to the tightness, the surface of the anodized element becomes tight and smooth, which makes the oxide coating resistant to atmospheric corrosion agents and reduces the tendency of impurities to settle on the surface of the product.

Corrosion test

(results obtained after 20,000 hours of exposure to salt spray)